MINCO Non-metallic case miniature RTD & Thermocouple sensors are designed for easy installation for industrial and commercial applications. These sensors can be installed directly into drilled holes in components such as bearings or machined parts, as well as onto surfaces of existing equipment. Non-metallic RTD & Thermocouple sensors can also be installed into end turn windings of motors and in other equipment. Standard cases are manufactured from DAP (Diallyl Phthalate) and elements are fully encapsulated with high temperature, thermally conductive epoxy. Due to the electrical insulation properties of the case material, these sensors are ideal for high voltage applications. Standard designs provide low cost options in a variety of sizes and configurations. Platinum RTD elements provide stable and reliable output compatible with most control and monitoring systems. Alternatively, interchangeable thermocouple designs allow you to easily customize your installation to different instrumentation.

• Wide temperature ranges of -50 to 200°C (-58 to 392°F) for RTDs and -184 to 200°C (-299 to 392°F) for thermocouples

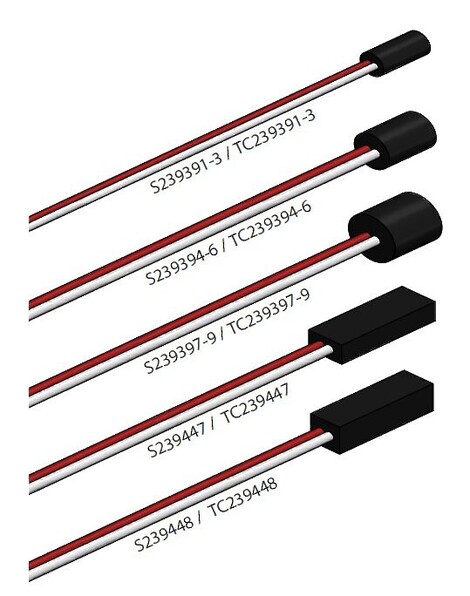

• Configurations to fit most applications

• Standard 100 ohm platinum and 1000 ohm platinum RTD elements, as well as nickel element options.

• Type E, J, K, or T thermocouple options

MINCO Non-Metallic Case Miniature Sensors

Non-metallic case miniature sensors are engineered for seamless and versatile installation in a wide range of industrial and commercial applications. These sensors can be effortlessly installed directly into drilled holes in components such as bearings, machined parts, and end turn windings of motors, as well as mounted onto the surfaces of existing equipment. This flexibility makes them ideal for retrofitting into existing systems without the need for extensive modifications.

Durable and Insulated Construction

Standard cases are meticulously manufactured from DAP (Diallyl Phthalate), a high-performance polymer known for its excellent electrical insulation properties and resistance to harsh environmental conditions. The sensing elements are fully encapsulated with high-temperature, thermally conductive epoxy, ensuring reliable performance even in extreme temperatures ranging from -184°C to 200°C. The non-metallic construction not only provides electrical insulation, making these sensors perfect for high voltage applications, but also offers superior resistance to moisture, chemicals, and mechanical stress.

Versatile and Cost-Effective Solutions

Designed with versatility in mind, these sensors are available in a variety of sizes and configurations to meet diverse application needs. Standard designs offer cost-effective options without compromising on quality, while customizable configurations allow for tailored solutions to fit specific requirements. Their compact form factor ensures they fit into confined spaces, making them suitable for high-density component testing and applications where space is at a premium.

Precision and Compatibility

Equipped with platinum RTD (Resistance Temperature Detector) elements, these sensors deliver stable and reliable outputs compatible with most control and monitoring systems. For applications requiring different instrumentation, interchangeable thermocouple designs are available, allowing for easy customization and integration into various setups. This ensures precise temperature measurements and seamless compatibility with existing data acquisition systems and process controllers.

Enhanced Durability and Performance

Non-metallic case miniature sensors are built to withstand rigorous industrial environments, offering excellent shock and vibration resistance. Their robust construction ensures long-term durability and consistent performance, even in demanding settings such as semiconductor manufacturing, automotive testing, and HVAC systems. Additionally, options for different lead-wire configurations and connector types enhance their adaptability to diverse installation scenarios.

Applications of Non-Metallic Case Miniature Sensors

These sensors are ideal for use in high voltage environments, motor windings, bearings, machined components, and various other industrial equipment. Their ability to provide accurate temperature monitoring in challenging conditions makes them indispensable for quality control, process optimization, and equipment maintenance across multiple industries.